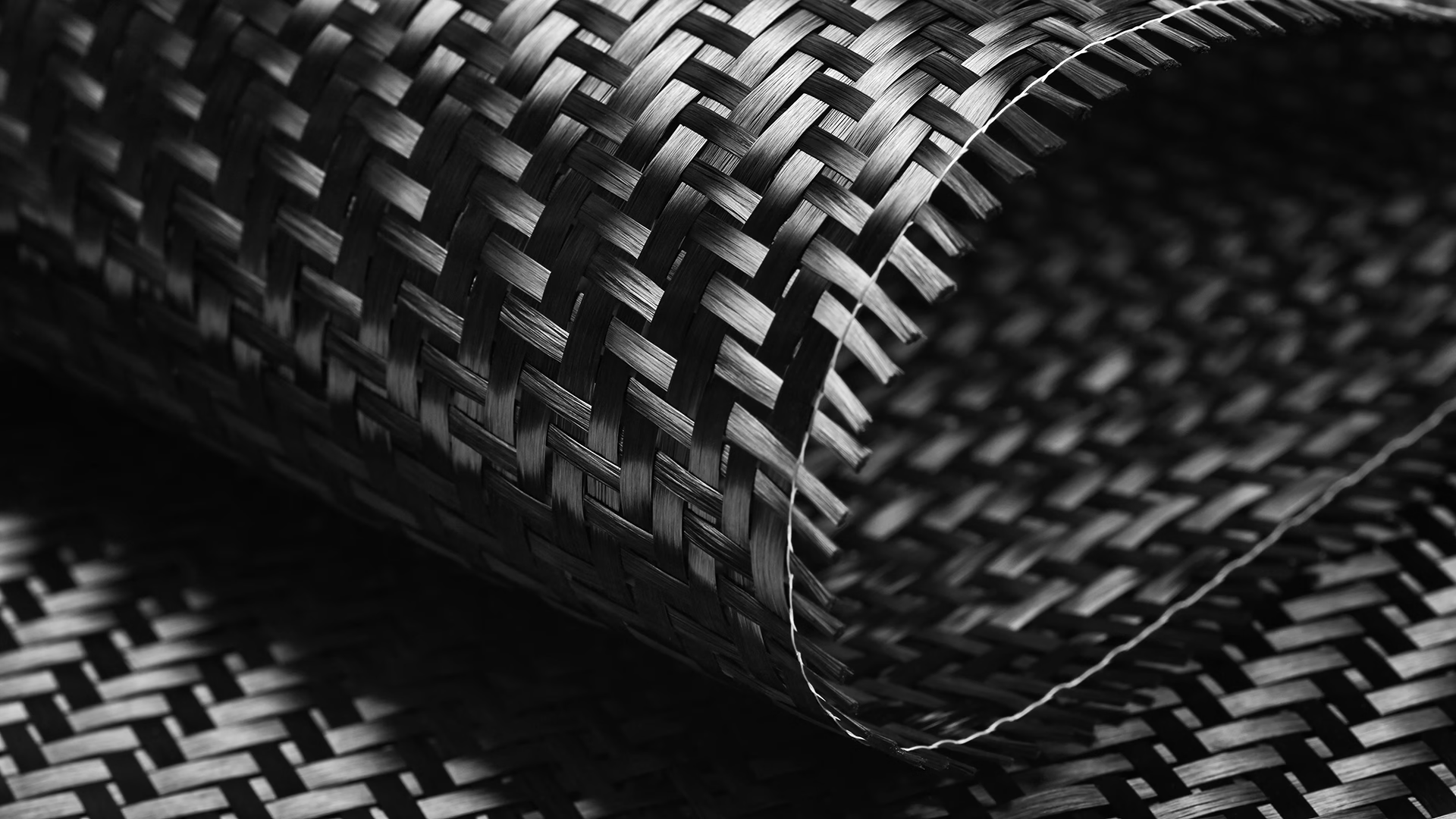

Delivering state-of-the-art fibre handling and processing machinery

As a technology partner to the traditional and technical fibre markets, we design and manufacture some of the most advanced fibre processing technologies in the world.

At our Innovation Centre, we operate a programme of collaborative innovation led by our world-class technology experts. Here, we work closely with international organisations to achieve more from their fibre processing operations, with technologies that improve process efficiency and product performance while reducing waste.

We work at the forefront of new markets, developing technologies to process advanced fibres including high-performance composites used in hydrogen, electrification and lightweighting for multiple industries from aerospace and automotive transport to wind energy and construction.

Products & Technologies

Cygnet Texkimp’s product range spans the complete composite lifecycle – from fibre unwinding to recycling. Each machine is engineered for accuracy, repeatability, and reliability, and supported by our service, spares, and innovation teams.

Industries & Sectors

Cygnet Texkimp technologies are used by some of the world’s most innovative manufacturers in aerospace, automotive, textiles, defence, medical, and renewable energy sectors. Our expertise spans both traditional and advanced fibre applications, from woven fabrics to composite components for next-generation transport and infrastructure.

Innovation & R&D

Where Ideas Become Industrial Reality

At the heart of Cygnet Texkimp’s innovation is our 15,000 sq ft Innovation Centre in Cheshire, UK – a collaborative research, testing, and development space for the global composites and advanced materials industry.

Here, we work with manufacturers, universities, and research institutes to develop new materials, refine processes, and validate commercial-scale production. Our engineers support customers from Technology Readiness Level (TRL) 5-6 through to industrialisation, helping bring ideas to life faster and more effectively.

Sustainability & DEECOM®

Cygnet Texkimp is pioneering sustainable composite manufacturing through DEECOM®, a pressolysis-based recycling technology that reclaims near-virgin carbon fibres without burning or solvents. This innovation helps manufacturers reduce waste, secure material supply, and achieve circular economy goals.